BESPOKE Functionalised Surfaces

ShimyaTech has developed technologies for chemical modification of different types of surfaces, allowing addition of various functionalities on surfaces for the purpose of tuning their properties for the desired applications. Application of the technology has already been demonstrated in areas such as: corrosion resistance, water and dirt repelling, antibiofilm surfaces and functionalised fabrics / medical devices.

We will be able to offer support and service for modification of most types of surfaces with hydrophobic and hydrophilic functionalities and/or to incorporate them with nanoparticles tailored to your needs.

Explore the examples of applications here:

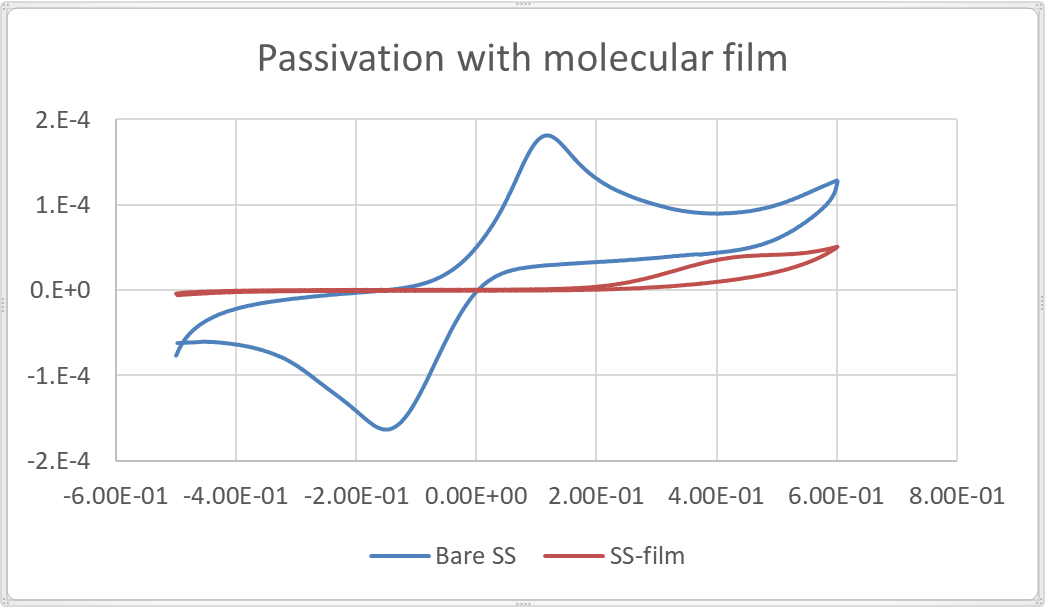

Example 1: The passivation of a hydrophobic film containing long alkyl chain chemically attached onto a stainless steel surface is compared with a similar bare metal as shown in THE Figure. This indicates the hydrophobic film prevents any electrochemical reaction on metal surface thus almost complete passivation to corrosion reactions.

Example 2: Hydrophobic molecular films for the preparation of dirt and water repellent surfaces on surfaces is desirable for specific applications such as self-cleaning materials. We have used Contact Angle measurements to demonstrate various properties for metal and non-metallic surfaces functionalised with hydrophilic and hydrophilic groups. For instance, Titanium slides have been functionalised with benzoic acid and alkyl benzene in order to induce water and dirt repellent property.

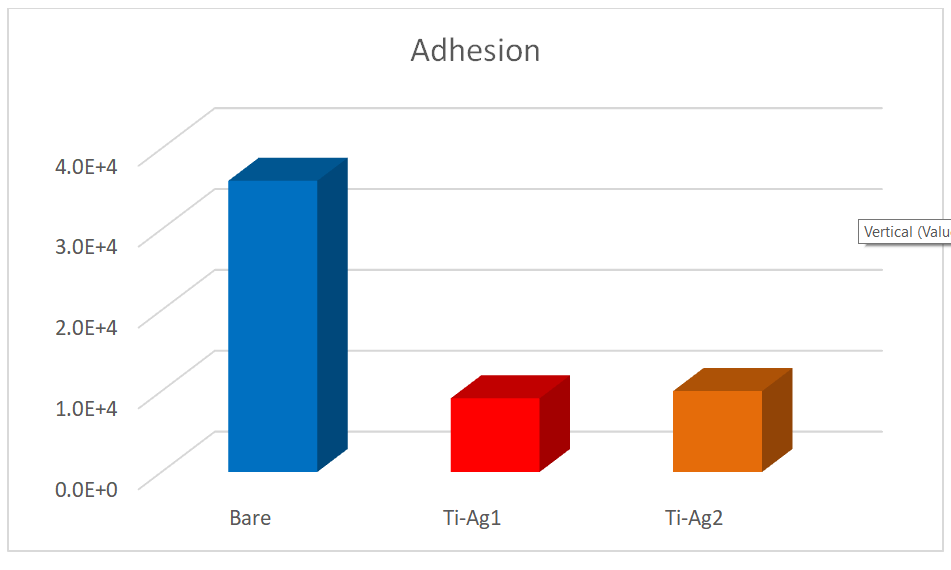

Example 3: Surface modifications and coatings are used for preventing bacterial adhesion and/or contact killing, thus preventing Biofilm Formation. Formation of biofilms follows three steps: Adhesion, Multiplication and Biofilm Formation. By preventing adhesion and adding a contact killing agent, biofilm formation can be prevented as shown below.

Modification of surfaces with silver nanoparticles, significantly reduces the formation of biofilms on various surfaces by both preventing adhesion and contact killing of bacteria.

ShimyaTech Ltd

Liverpool Science Park

131 Mount Pleasant

Liverpool, UK

L3 5TF

info@shimyatech.com

Located close to the M62/M6/M56 motorway network, ShimyaTech is easily accessible for our clients from much of England and Wales. For international clients, Liverpool and Manchester International Airports can accommodate most suitable travel routes.

[pt_view id=”9cdeb1fnef”]